PRODUCTS

Contact Us

Phone

Address

No. 60, Yunjing East Road, Liyuan Town, Tongzhou District, Beijing City, China

Micro Rotor Reactor

Compact design for solid-involved reactions.

keywords:

Category:

PRODUCTS

Micro Rotor Reactor

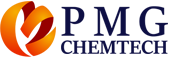

Process Intensification Principles

● Low liquid holdup, suitable for solid-involved microreactors.

● Generates a stable and adjustable centrifugal force field via high-speed rotation, simulating a hypergravity environment (>100× Earth’s gravity). Overcomes limitations of traditional gravity on mass transfer, significantly enhancing molecular diffusion and interphase mass transfer efficiency.

● Gap between fixed shell and rotating disk: 0.5–2 mm.

● Under hypergravity and intense shear forces, multiphase systems (gas-liquid, liquid-liquid, liquid-solid) are fragmented into nanoscale films, filaments, or droplets, enabling rapid phase interface renewal and improved micromixing/mass transfer.

Product Features

● High mass transfer efficiency.

● Suitable for processing solid-containing or high-viscosity materials.

● Ideal for gas-liquid reactions with high gas-liquid ratios.

● Low pressure drop, enabling large-scale throughput amplification.

● Minimal liquid holdup, suitable for handling expensive substances.

● High flooding gas velocity and low gas pressure drop.

● Excellent micromixing performance, ideal for nanomaterial synthesis via reactive precipitation.

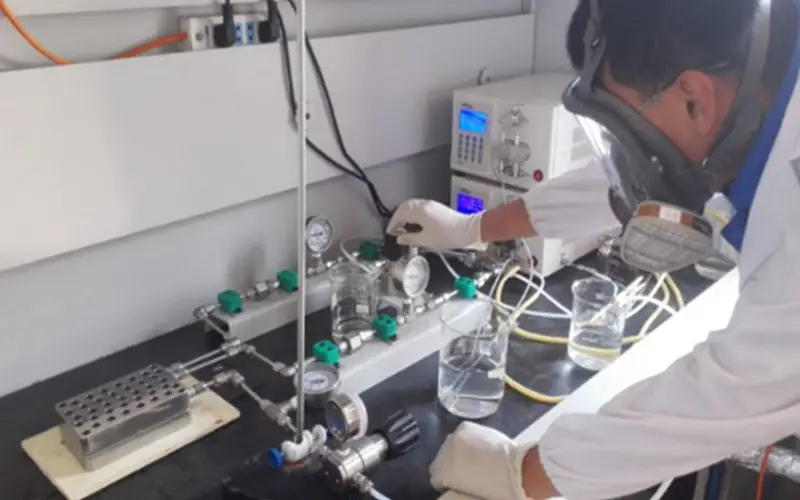

Structure & Parameter

|

Micro Rotor Reactor | SL10403 | SL10503 | SL10803 | SL11303 | ||

| Liquid Holdup (mL) | 100 | 200 | 500 | 1000 | |||

| Design Pressure (MPa) | 5MPa | ||||||

| Design Temperature (°C) | -40~300(Customizable) | ||||||

| Plate Material | 316L,C276,Sic, Zirconium etc. | ||||||

| Number of Reaction Chambers | 1-5(Customizable) | ||||||

| Rotation Speed | 1500r/min (Adjustable) | ||||||

| Agitator Type | Disc Agitator | ||||||

| Sealing Type | Magnetic Seal or Mechanical Seal | ||||||

| Dimensions | 300*300*1000 | 400*400*1000 | 500*500*1200 | ||||

| Compatible Phases | Gas, Liquid, Solid phases | ||||||

| Suitable Range | Reaction Type |

| Reaction | Nitration, Chlorination, Ammoniation, Butyllithium Reactions, Addition, Diazotization, Oxidation, etc. |

| Crystallization. | LiFePO₄, Li₂CO₃, Inorganic Salt Crystallization, Pharmaceutical Nanonization, Emulsion Preparation |

Previous page

Next page

Precision Flow, Modular Systems,Green Synthesis

Patents

Industrial Cases

Clients

Chemical Reactions Supported

Why Choose PMG ChemTech?

Lead the Future of Continuous Flow Technology

Industry-Leading Full-Scenario Solutions

At PMG ChemTech, we don’t just build reactors—we revolutionize chemical manufacturing. With the most comprehensive portfolio of continuous flow reactors in the industry, we deliver tailored “one-stop” solutions for sectors ranging from pharmaceuticals and agrochemicals to specialty materials and green chemistry.

Core Technologies Driving Industrial Innovation

● Fluid Dynamics Expertise

● Synthesis & Scale-Up Mastery

● Separation Precision

● Engineering Excellence

The PMG Advantage: Brains Behind the Breakthroughs

6 PhDs, 5 senior engineers, and multidisciplinary experts in organic synthesis, chemical engineering, automation, and fluid mechanics.

Trusted by Global Leaders

With 30+ patents, 50+ industrial success stories, and partnerships spanning 150+ clients, PMG ChemTech has optimized 400+ chemical reactions worldwide. From Fortune 500 giants to innovative SMEs, we empower industries to embrace continuous, automated, and intelligent manufacturing.

Join the Continuous Flow Revolution

Why settle for outdated batch processes? PMG ChemTech equips you with the technology to:

✅ Slash operational costs by 30-50%

✅ Reduce carbon footprint through energy-efficient designs

✅ Eliminate safety risks with automated, closed-loop systems

✅ Accelerate time-to-market with rapid scale-up capabilities

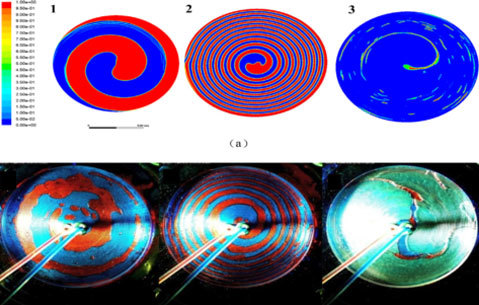

A comprehensive service system

Whether it's technical consultation or business inquiries, we promise to provide an initial response within 24 hours. From laboratory testing to industrial production, we offer one-stop services to ensure seamless integration at every stage.

Ready to Transform Your Chemical Processes?

Contact Us Today for a FREE Consultation or Request a Customized Solution!

GET IN TOUCHPrecision Manufacturing

Interested in our product

Enter your contact information and we will contact you as soon as possible

Science Laboratory

Packaging and transportation

Other Products

PMG ChemTech is committed to driving the global chemical industry towards continuous, automated, and intelligent transformation, offering efficient, safe, and sustainable chemical manufacturing solutions to our clients