PRODUCTS

Contact Us

Phone

Address

No. 60, Yunjing East Road, Liyuan Town, Tongzhou District, Beijing City, China

Multiphase Reactor

The Most Widely Applicable Continuous Reactor ● High Mass Transfer and Heat Exchange Efficiency ● Short Residence Time, High Space-Time Yield ● Improved Product Quality ● Single-Unit Throughput Up to 12,000 t/a ● Skid-Mounted Frame, Mobile and Stackable

keywords:

Category:

PRODUCTS

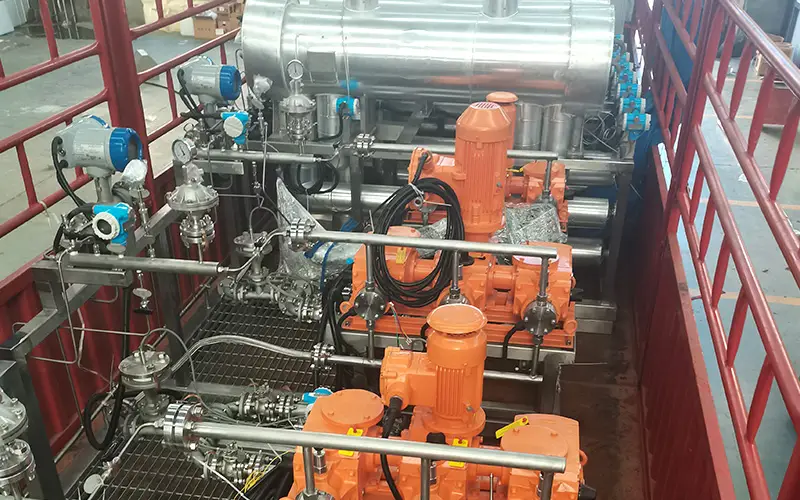

PMG Multiphase Reactor

What is a Multiphase Reactor?

The PMG Multiphase Reactor is a continuous reactor suitable for gas-liquid-solid multiphase reactions. It features a tube length significantly greater than its diameter and is equipped with a customized stirring system. The flow state approximates ideal plug flow with minimal backmixing. This equipment overcomes the limitations of traditional microchannel reactors, effectively solving the challenges of continuous reactions involving solid materials. It is suitable for catalytic hydrogenation, high-solid-content synthesis, and complex multiphase processes.

Technical Advantages of PMG Multiphase Reactors

Efficient Mass Transfer and Mixing Capability

● High Mass Transfer Efficiency: The mass transfer coefficient is 10–100 times higher than that of conventional reactors. The exponentially increased interfacial area between reactants enhances contact efficiency, significantly boosting reaction rates and reducing reaction time.

● Turbulence-Enhanced Mixing: Customized paddles and highly turbulent design break through multiphase interfacial tension, achieving macro-mixing on a small scale and micro-uniform dispersion.

Precise Heat Transfer and Temperature Control

● Dual Heat Exchange System: Internal and external heat exchange structures combined with high turbulence significantly improve heat transfer efficiency, allowing precise control of reaction temperature.

High Processing Capacity and Applicability

● Large Throughput: Single-unit annual processing capacity up to 200,000 tons, meeting industrial-scale continuous production needs.

● High Solid Content Handling: Maximum solid content up to 52%, overcoming traditional reactor limitations on solid materials.

● Multiphase Compatibility: Suitable for gas-liquid, liquid-liquid, and gas-liquid-solid three-phase reactions, supporting high-difficulty processes like hydrogenation catalysis.

Process Stability and Controllability

● Continuous Steady-State Operation: Radial parameters (concentration, temperature) vary only with flow direction, ensuring stable and controllable reaction processes.

● Uniform Residence Time: Radial flow velocity is uniform, ensuring consistent material residence time, improving product uniformity and yield.

Low Energy Consumption and Safety Design

● Low Pressure Drop and Energy Consumption: Optimized fluid path and stirring design reduce energy loss, lowering operating costs.

● Safe and Reliable: Enclosed moving parts reduce leakage points; low-noise operation complies with industrial safety and environmental standards.

Flexible Customization Capability

● Modular Structure: Skid-mounted frame design supports quick installation, mobility, and expansion, adapting to diverse production scenarios.

● Adjustable Parameters: Stirring intensity, heat exchange methods, etc., can be customized according to process needs, suitable for complex systems like high viscosity and high solid content.

Multiphase Reactor | Structure and Parameters

|

|

Multiphase Reactor |

SL2001 |

SL2002 |

SL2080 |

SL2200 |

|

|

Liquid Holdup (L) |

1 |

2 |

80 |

200 |

||

|

Design Pressure (MPa) |

0-2.5 MPa |

|||||

|

Design Temperature (°C) |

-20 to 200 (customizable) |

|||||

|

Material |

Titanium Alloy, 316L, Hastelloy C276, Zirconium, etc. |

|||||

|

Rotation Speed |

300 rpm |

|||||

|

Sealing Type |

Mechanical Seal |

|||||

|

Dimensions (mm) |

1200*700*1200 |

2500*1000*1800 |

||||

|

Compatible Phases |

Gas, Liquid, Solid |

|||||

|

Compatible Reactions |

Nitration, Chlorination, Ammoniation, Diazotization, Oxidation, Diazocoupling,Friedel-Crafts Acylation,etc. |

|||||

Industrial Applications of Multiphase Reactors

|

Reaction type |

Reaction Equation |

Reaction Type |

Reaction Equation |

|

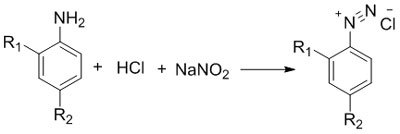

Diazotization |

|

Nitration Reaction |

|

|

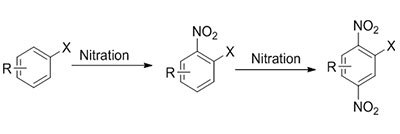

Diazocoupling |

|

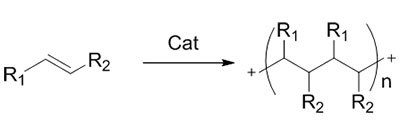

Polymerization |

|

|

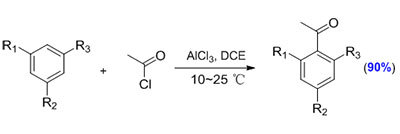

Friedel-Crafts Acylation |

|

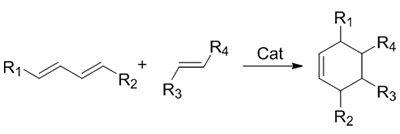

Addition Reaction |

|

|

|

Previous page

Next page

Precision Flow, Modular Systems,Green Synthesis

Patents

Industrial Cases

Clients

Chemical Reactions Supported

Why Choose PMG ChemTech?

Lead the Future of Continuous Flow Technology

Industry-Leading Full-Scenario Solutions

At PMG ChemTech, we don’t just build reactors—we revolutionize chemical manufacturing. With the most comprehensive portfolio of continuous flow reactors in the industry, we deliver tailored “one-stop” solutions for sectors ranging from pharmaceuticals and agrochemicals to specialty materials and green chemistry.

Core Technologies Driving Industrial Innovation

● Fluid Dynamics Expertise

● Synthesis & Scale-Up Mastery

● Separation Precision

● Engineering Excellence

The PMG Advantage: Brains Behind the Breakthroughs

6 PhDs, 5 senior engineers, and multidisciplinary experts in organic synthesis, chemical engineering, automation, and fluid mechanics.

Trusted by Global Leaders

With 30+ patents, 50+ industrial success stories, and partnerships spanning 150+ clients, PMG ChemTech has optimized 400+ chemical reactions worldwide. From Fortune 500 giants to innovative SMEs, we empower industries to embrace continuous, automated, and intelligent manufacturing.

Join the Continuous Flow Revolution

Why settle for outdated batch processes? PMG ChemTech equips you with the technology to:

✅ Slash operational costs by 30-50%

✅ Reduce carbon footprint through energy-efficient designs

✅ Eliminate safety risks with automated, closed-loop systems

✅ Accelerate time-to-market with rapid scale-up capabilities

A comprehensive service system

Whether it's technical consultation or business inquiries, we promise to provide an initial response within 24 hours. From laboratory testing to industrial production, we offer one-stop services to ensure seamless integration at every stage.

Ready to Transform Your Chemical Processes?

Contact Us Today for a FREE Consultation or Request a Customized Solution!

GET IN TOUCHPrecision Manufacturing

Interested in our product

Enter your contact information and we will contact you as soon as possible

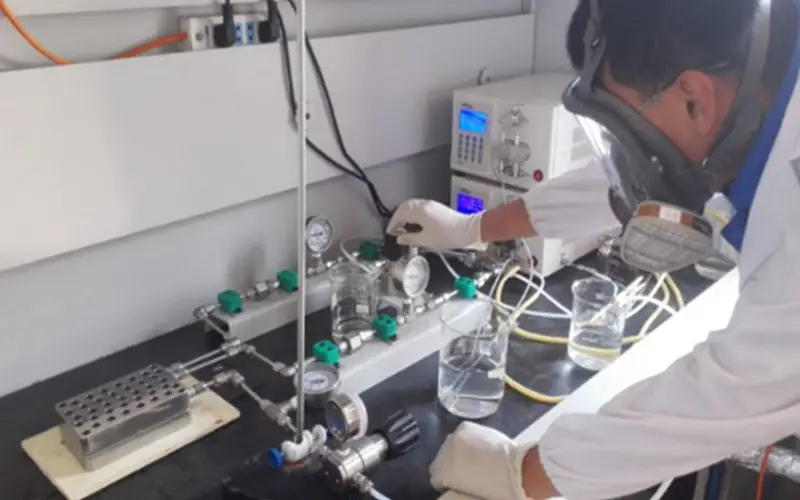

Science Laboratory

Packaging and transportation

Other Products

PMG ChemTech is committed to driving the global chemical industry towards continuous, automated, and intelligent transformation, offering efficient, safe, and sustainable chemical manufacturing solutions to our clients