PRODUCTS

Contact Us

Phone

Address

No. 60, Yunjing East Road, Liyuan Town, Tongzhou District, Beijing City, China

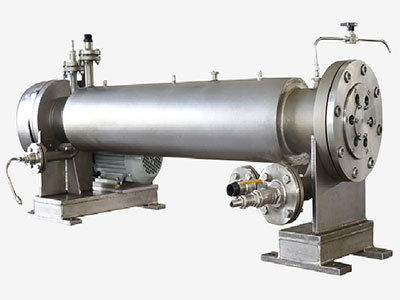

Reaction Crystallizer

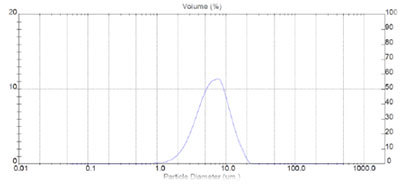

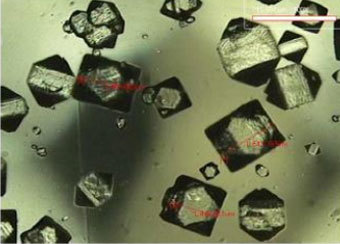

Achieve uniform particle size distribution.

keywords:

Category:

PRODUCTS

Reaction Crystallizer

Structure of PMG Reaction Crystallizer

● Composed of two concentric inner and outer cylinders.

● The inner cylinder rotates at high speed, driving the reaction liquid to form alternating and orderly arranged fluid vortices, achieving thorough and regular mixing.

Structural Features

High Mixing Efficiency

● Minimal axial backmixing, high reaction driving force.

● Vortex columns provide a large specific surface area for the reaction medium.

● High mass transfer coefficient combined with low shear force.

Stirring and Fluidization Capabilities

● Gentle yet effective stirring to enhance gas-liquid mixing.

● Maintains uniform fluidization of solid catalyst particles; even at low axial flow rates, optimal fluidization is achieved by adjusting the inner cylinder speed.

Product Structure and Parameters

|

PMG Crystallizer |

SLCTR-02 |

SLCTR-1 |

SLCTR-50 |

SLCTR-1000 |

|

Liquid Holdup (L) |

0.2 |

1 |

50 |

500 |

|

|

Design Pressure (MPa) |

0-2MPa (Standard) / 0-5MPa (Customized) |

||||

|

Design Temperature (℃) |

0–90°C (Standard) / -20–400°C (Customized) |

||||

|

Reaction Plate Material |

316L, Hastelloy C-276, Zirconium, Teflon, etc. |

||||

|

Rotation Speed |

1500 rpm (Standard) |

||||

|

Sealing Type |

Magnetic Seal / Mechanical Seal |

||||

|

Dimensions (mm) |

1100*700* 1200 |

1400*700*1200 |

3400*1300*1600 |

8500*3000*2300 |

|

|

Compatible Phases |

Gas, Liquid, Solid |

||||

|

Compatible Reactions |

Nitration, Chlorination, Ammoniation, Diazotization, Oxidation, Crystallization, etc. |

||||

|

Main Products |

|||

|

LiFePO4 |

Ba(NO3)2 |

NiSO4 |

KNO3 |

|

(NiMnCo)(OH) 2 |

CoSO4 |

Li2CO3 |

NaHCO3 |

|

TiO2 |

CaCO3 |

Durene |

Methionine |

|

K2CO3 |

GMP |

NH4H2PO4 |

SiO2 |

|

IMP |

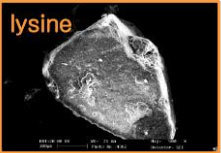

Lysine |

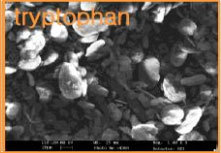

Tryptophan |

SMZ |

|

Main Process |

||

|

Crystallization |

Photocatalysis |

Regeneration |

|

Recrystallization |

Polymerization |

Extraction |

|

Co-precipitation |

Free radical reaction |

Particle loading |

|

Dehydration |

Enzymatic catalysis |

Membrane separation |

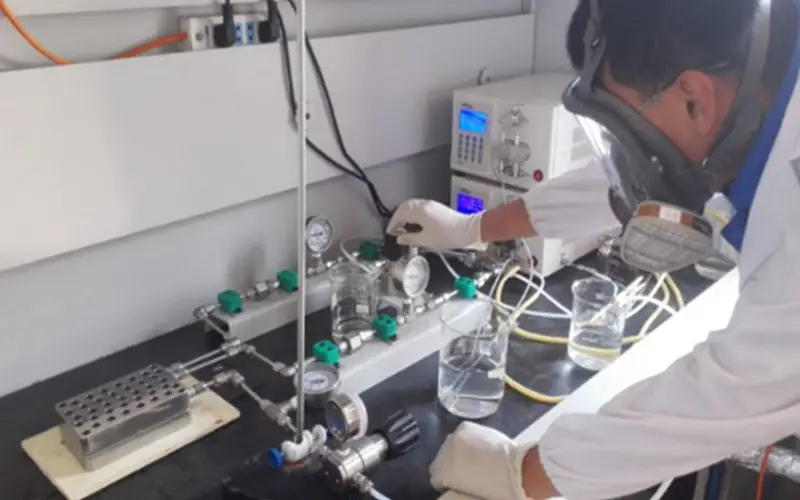

Industrial Cases and Achievements

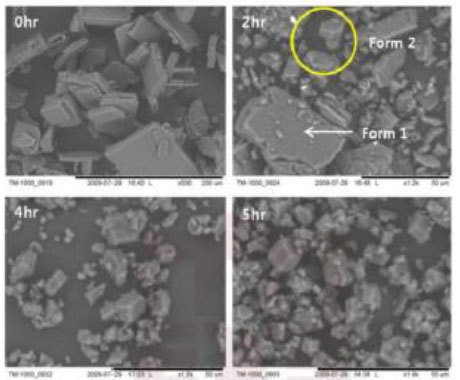

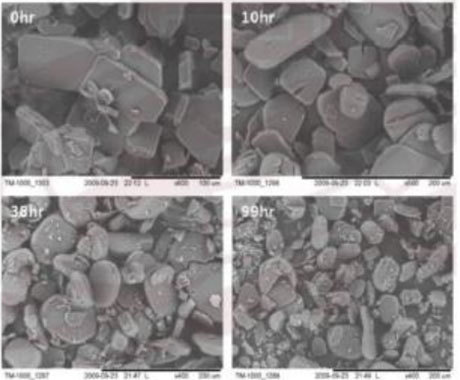

Pharmaceutical industry Sulfamethoxazole SMZ

|

|

|

|

|||||||||

|

|

|

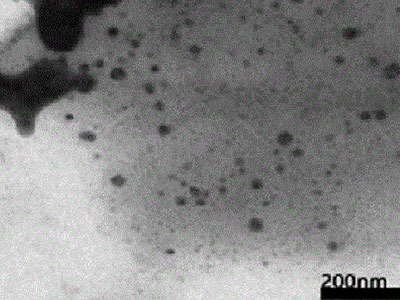

Graphene oxide

|

|

| Parameter | Batch Reactor | PMG | |

| Production Method | Batch | Continuous | |

| Reaction Temp.(℃) | 30 | 20 | |

| Recovery Rate(%) | 70 | 95↑ | |

| Reaction Time(h) | Max 120 | 1↓ | |

| Production Cost(CNY/g) | 3000 | 300 | |

Amino acid

|

|

|

| Parameter | Batch Reactor | PMG Reaction Crystallizer |

| Production Method | Batch | Continuous |

| Crystallization Time | 8~9h | 5min |

| Energy Consumption (TOE/ton) | 25200 | 15200 |

| Purity (%) | 97 | 99.9 |

| Crystallinity (%) | 90 | 98 |

| Equipment Volume | 21m³ | 270L |

| Production Cost (CNY/kg) | 96.4 | 43.6 |

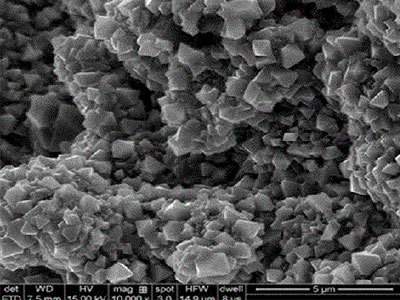

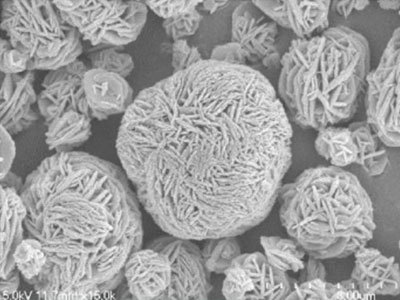

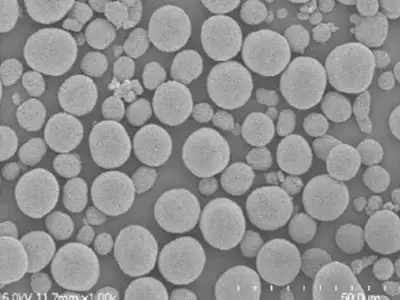

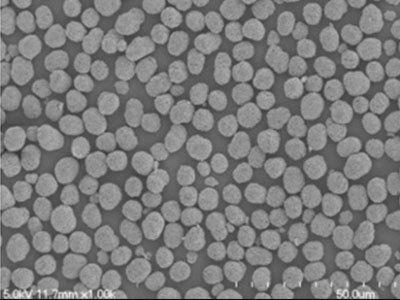

Metal Powders

|

|

| Parameter | Reactor | PMG Reaction Crystallizer |

| Production Method | Batch | Continuous |

| Reaction Time | 2h | 0.6h |

| Particle Size (μm) | 70 | 7 |

| Non-uniformity([D90-D10]/D50) | 3.418 | 1.726 |

OLED Luminescent Materials

| Parameter | Reactor | PMG Reaction Crystallizer |

| Production Method | Batch | Continuous |

| Process Type | Dry Process | Wet Process |

| Temperature (°C) | 270~280℃ | Room Temperature |

| Purity (%) | 99.95 | 99.99 |

| Operating Pressure | vacuum | Atmospheric |

| Production Time | 12~24h | 1h |

| Production Cost (CNY/kg) | 60000 | 18000 |

CNT Washing

| Parameter | Dialysis Method | PMG Reaction Crystallizer |

| Mockups |  |

|

| Washing Time | 168h | 1.66h |

| Washing Solution Usage | 70L | 4L |

| Post-Wash pH | 6 | 6 |

Processing Time Reduction: 99% ↓

Washing Solution Consumption Reduction: 94.2%

Waste Phosphoric Acid to Ammonium Phosphate

|

||

| Parameter | Batch Reactor | PMG Reaction Crystallizer |

| Production Method | Batch | Continuous |

| Processing Time (h) | 3 | 0.5 |

| Particle Size(μm) | 300 | 500 |

| Purity(%) | 99.5 | 99.5 |

| Recovery Rate (%) | 80 | 85 |

Prepare inorganic compounds

Potassium Carbonate, K₂CO₃

|

Parameter | Batch Process | Continuous Process |

| Recovery Rate (%) | 60 | 80↑ (33% Improvement) | |

| Time (h) | 3 | 0.5↓ (83.3% Faster) | |

| Hydrate Forms | K₂CO₃·5H₂O | K₂CO₃·1.5H₂O |

Lithium Carbonate, Li₂CO₃

|

Parameter | Batch Process | Continuous Process |

| Purity (%) | 99.5 | 99.5 | |

| Particle Size (μm) | 100 | >200↑ (Enhanced Filtration) | |

| Reaction Time (h) | 3 | 0.5↓ (83.3% Faster) |

High-Purity Recrystallization

Nal:Chlorine Removal

|

Parameter | Batch Process | Continuous Process |

| Particle Size Distribution | Non-uniform | Uniform↑ (CV <5%) | |

| Impurity (ppm) | 2000 | 0↓ (Zero Residual) | |

| Recovery Rate (%) | 95 | 99↑ (4.2% Improvement) |

Barium Chlorate: Heavy Metal Removal

|

Parameter | Batch Process | Continuous Process |

| Recovery Rate (%) | 80 | 85↑ (6.25% Improvement) | |

| Reaction Time (h) | 4 | 1↓ (75% Faster) | |

| Heavy Metal Concentration (ppm) | 10 | <2.5↓ (EPA Compliance) |

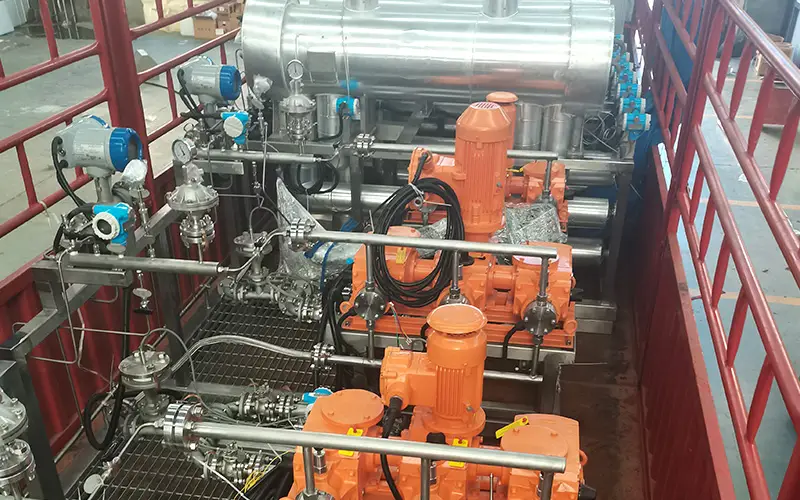

Industrial Production

|

Lithium battery industry case |

Parameter | Batch Reactor | PMG Crystallizer |

| Manpower | 6 | 3 | |

| Footprint | 40m2 | 6m2 | |

| Efficiency | 10 hours | 3 hours | |

| Particle size (μm) | 5~20 | 1~15 | |

| Non-uniformity Index | 0.5 | 0.2 | |

| Tapped Density (g/ml) | 2.1 | 2.2 | |

| Equipment Cost | Low | Slightly lower | |

| Production method | Batch | Continuous |

|

Amino Acid Crystals |

Item | Batch Reactor | PMG Crystallizer |

| Efficiency | 8~9 hours | 5 minutes | |

| Purity (%) | 97% | 99.90% | |

| Crystallinity (%) | 90% | 98% | |

| Equipment volume | 21m³ | 300L | |

| Production Method | Batch | Continuous |

Industrialized Skid-Mounted Equipment

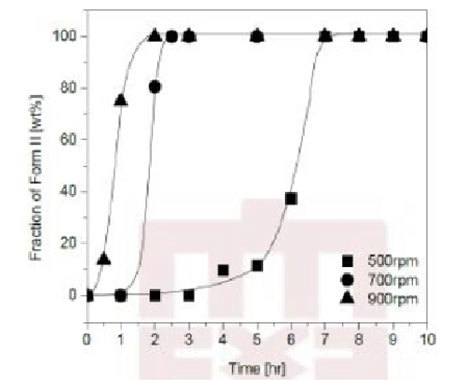

1–25 μm Particle Modulation Process

Particle Uniformity Performance

Previous page

Next page

Precision Flow, Modular Systems,Green Synthesis

Patents

Industrial Cases

Clients

Chemical Reactions Supported

Why Choose PMG ChemTech?

Lead the Future of Continuous Flow Technology

Industry-Leading Full-Scenario Solutions

At PMG ChemTech, we don’t just build reactors—we revolutionize chemical manufacturing. With the most comprehensive portfolio of continuous flow reactors in the industry, we deliver tailored “one-stop” solutions for sectors ranging from pharmaceuticals and agrochemicals to specialty materials and green chemistry.

Core Technologies Driving Industrial Innovation

● Fluid Dynamics Expertise

● Synthesis & Scale-Up Mastery

● Separation Precision

● Engineering Excellence

The PMG Advantage: Brains Behind the Breakthroughs

6 PhDs, 5 senior engineers, and multidisciplinary experts in organic synthesis, chemical engineering, automation, and fluid mechanics.

Trusted by Global Leaders

With 30+ patents, 50+ industrial success stories, and partnerships spanning 150+ clients, PMG ChemTech has optimized 400+ chemical reactions worldwide. From Fortune 500 giants to innovative SMEs, we empower industries to embrace continuous, automated, and intelligent manufacturing.

Join the Continuous Flow Revolution

Why settle for outdated batch processes? PMG ChemTech equips you with the technology to:

✅ Slash operational costs by 30-50%

✅ Reduce carbon footprint through energy-efficient designs

✅ Eliminate safety risks with automated, closed-loop systems

✅ Accelerate time-to-market with rapid scale-up capabilities

A comprehensive service system

Whether it's technical consultation or business inquiries, we promise to provide an initial response within 24 hours. From laboratory testing to industrial production, we offer one-stop services to ensure seamless integration at every stage.

Ready to Transform Your Chemical Processes?

Contact Us Today for a FREE Consultation or Request a Customized Solution!

GET IN TOUCHPrecision Manufacturing

Interested in our product

Enter your contact information and we will contact you as soon as possible

Science Laboratory

Packaging and transportation

Other Products

PMG ChemTech is committed to driving the global chemical industry towards continuous, automated, and intelligent transformation, offering efficient, safe, and sustainable chemical manufacturing solutions to our clients