PRODUCTS

Contact Us

Phone

Address

No. 60, Yunjing East Road, Liyuan Town, Tongzhou District, Beijing City, China

Fully Automated Hydrogenation Reactor

The equipment is suitable for various hydrogenation reaction scenarios

keywords:

Category:

PRODUCTS

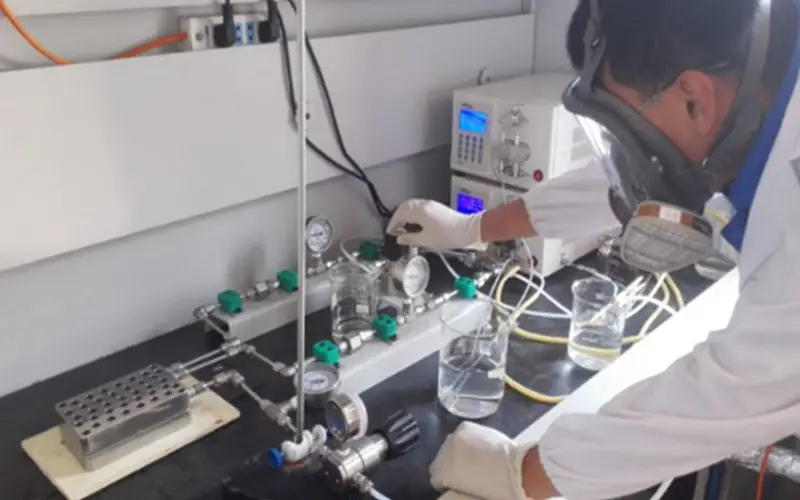

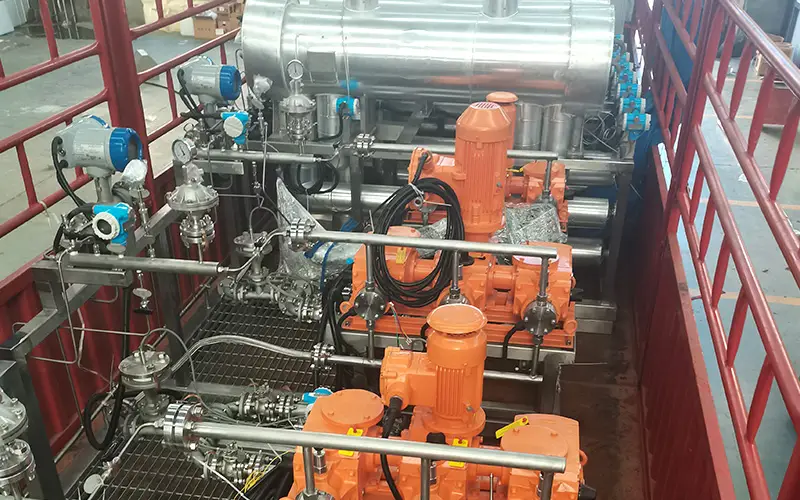

Fully Automated Hydrogenation System

Equipment Core Components:

● HPLC Pump: Ensures precise delivery of reactants.

● Dual Gas Feeding System: Adjusts gas mass flow rate for stable supply.

● MC Gas-Liquid Mixer: Enhances gas-liquid mixing and mass transfer efficiency.

● Reaction Chamber: Equipped with solid catalyst for reactions with preheated mixtures.

● Automatic Back Pressure Valve: Maintains stable reaction conditions by regulating back pressure.

| Automatic Micro-reaction Hydrogenation | Gas Feeder | Liquid Feeder | Automatic Back Pressure Valve |

|

|

|

|

Advantages Over Traditional Batch High-Pressure Hydrogenation Reactors

● Continuous Operation: Microchannel mixer resolves gas-liquid mixing inhomogeneity and low mass transfer rates.

● High Mass Transfer Efficiency: Leverages plug-flow characteristics for high-selectivity deprotection and significantly reduced reaction time.

Key Advantages

● Full Automation: Automated process control minimizes human error and ensures batch-to-batch consistency.

● Enhanced Hydrogenation Process: Integrated MC gas-liquid mixing module optimizes mixing and mass transfer.

● Inherent Safety: Low in-process liquid holdup with high throughput, supports kilogram-scale customization, and ensures operational safety.

● Compact Design: Space-saving, highly integrated system compatible with fume hood operation.

● Broad Operating Conditions:

● Maximum Reaction Temperature: 200°C,Maximum Reaction Pressure: 10 MPa

● Online Monitoring & Sampling: Equipped with automatic sampling ports and online UV detectors for real-time analysis.

Structure and Parameters

| Model | Hydro-Lab-S10 | Hydro-Lab-H10 | Hydro-Lab-S50 | Hydro-Lab-H50 |

| Material | 316L | HC276 | 316L | HC276 |

| Liquid Holdup | 5.6ml | 150.7ml | ||

| Catalyst Particle Size | 0.2-2mm | |||

| Reaction Pressure | <10MPa | |||

| Reaction Temperature | Room temperature-200℃ | |||

| Preheater Temperature | Room temperature-200℃ | |||

| Liquid Feed Flow Rate | 0.02-9.999ml/min | 0.1-50.0ml/min | ||

| Hydrogen Feed Flow Rate | 5-100sccm | 5-100sccm | ||

| Nitrogen Feed Flow Rate | 5-100sccm | 5-100sccm | ||

| Liquid Feed Accuracy | ±2%FS | |||

Catalysts & Technical Support

Customized catalyst selection and sizing recommendations based on client requirements.

| Carbon-loaded Catalysts |  |

|

| Palladium on Carbon(Pd/C:Pd%:0.1~30) | Platinum on Carbon(Pt/C:Pt%:0.1~60) | |

| Ruthenium on Carbon(Ru/C:Ru%:0.1~10) | Rhodium on Carbon(Rh/C:Rh%:0.1~10) | |

| Gold on Carbon(Au/C:Au%:0.1~10) | Palladium Hydroxide on Carbon(Pd(OH)/C:Pd%:0.1~30) | |

| Other Support Catalysts | ||

| Alumina-Supported Noble Metal Catalysts | Titania-Supported Metal Catalysts | |

| Molecular Sieve-Supported Noble Metal Catalysts | Inorganic Salt-Supported Noble Metal Catalysts | |

| Silica-Supported Noble Metal Catalysts | Resin-Supported Noble Metal Catalysts | |

| Non-Precious Metal Catalysts | ||

| Copper-Based Catalysts | Nickel-Based Catalysts | |

| Iron-Based Catalysts | Cobalt-Based Catalysts | |

| Manganese-Based Catalysts | Molecular Sieve Catalysts | |

Previous page

Next page

Precision Flow, Modular Systems,Green Synthesis

Patents

Industrial Cases

Clients

Chemical Reactions Supported

Why Choose PMG ChemTech?

Lead the Future of Continuous Flow Technology

Industry-Leading Full-Scenario Solutions

At PMG ChemTech, we don’t just build reactors—we revolutionize chemical manufacturing. With the most comprehensive portfolio of continuous flow reactors in the industry, we deliver tailored “one-stop” solutions for sectors ranging from pharmaceuticals and agrochemicals to specialty materials and green chemistry.

Core Technologies Driving Industrial Innovation

● Fluid Dynamics Expertise

● Synthesis & Scale-Up Mastery

● Separation Precision

● Engineering Excellence

The PMG Advantage: Brains Behind the Breakthroughs

6 PhDs, 5 senior engineers, and multidisciplinary experts in organic synthesis, chemical engineering, automation, and fluid mechanics.

Trusted by Global Leaders

With 30+ patents, 50+ industrial success stories, and partnerships spanning 150+ clients, PMG ChemTech has optimized 400+ chemical reactions worldwide. From Fortune 500 giants to innovative SMEs, we empower industries to embrace continuous, automated, and intelligent manufacturing.

Join the Continuous Flow Revolution

Why settle for outdated batch processes? PMG ChemTech equips you with the technology to:

✅ Slash operational costs by 30-50%

✅ Reduce carbon footprint through energy-efficient designs

✅ Eliminate safety risks with automated, closed-loop systems

✅ Accelerate time-to-market with rapid scale-up capabilities

A comprehensive service system

Whether it's technical consultation or business inquiries, we promise to provide an initial response within 24 hours. From laboratory testing to industrial production, we offer one-stop services to ensure seamless integration at every stage.

Ready to Transform Your Chemical Processes?

Contact Us Today for a FREE Consultation or Request a Customized Solution!

GET IN TOUCHPrecision Manufacturing

Interested in our product

Enter your contact information and we will contact you as soon as possible

Science Laboratory

Packaging and transportation

Other Products

PMG ChemTech is committed to driving the global chemical industry towards continuous, automated, and intelligent transformation, offering efficient, safe, and sustainable chemical manufacturing solutions to our clients