PRODUCTS

Contact Us

Phone

Address

No. 60, Yunjing East Road, Liyuan Town, Tongzhou District, Beijing City, China

Grignard Reactor

Continuous preparation of Grignard reagents.

keywords:

Category:

PRODUCTS

Grignard Reactor

Principles

● Chemical Formula of Grignard Reagent: R-Mg-X (R: organic group; X: halogen).

● The high electropositivity of magnesium polarizes the carbon atom to exhibit negative charge, forming a strong nucleophile that readily participates in reactions.

● Traditional processes require a strictly anhydrous and oxygen-free environment, with precise control of initiation and reaction temperatures to ensure safety.

Product Features

|

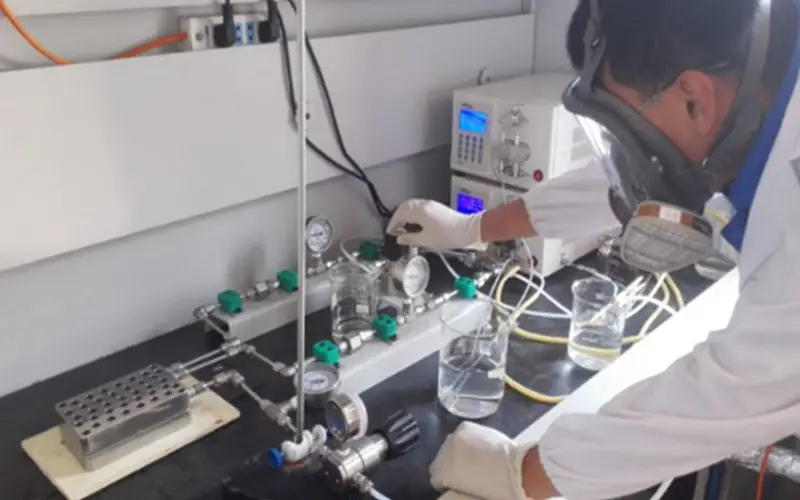

Process Advantages No entrainment of magnesium chips or coupling byproducts, ensuring high product purity. Rapid initiation mechanism enables low reaction temperatures and achieves 99.99% conversion. External circulation mechanism supports control of highly exothermic reactions. Industrialization Advantages Multi-stage serial connection design ensures thorough reactions and immediate product use, eliminating waiting time. Compact reactor size reduces footprint, labor requirements, and investment costs. |

|

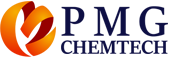

Core Functions and Structural Design

|

- Continuous Preparation System Continuous Feeding and Automated Control Fully automated continuous feeding mode simplifies operation and is suitable for large-scale industrial production. Closed System with Nitrogen Protection The reactor is fully sealed and purged with nitrogen to isolate oxygen, preventing flammable or explosive risks.

- Temperature Management Module Segmented Temperature Control Design The reactor is divided into multiple independent temperature zones, each precisely controlled: Initiation zone temperature > reaction zone temperature to avoid energy accumulation and rapid exothermicity. Multiple measurement points for real-time temperature monitoring to ensure reaction safety. High-Efficiency Heat Exchange System Large surface area design enhances heat exchange efficiency. Combined with precise temperature control, this reduces manual operation risks.

- Material Flow Optimization Continuous and uniform magnesium powder feeding ensures stable settling. Bottom-to-top plug flow design for liquid reactants enables gradual reaction initiation. |

Structure and parameters

|

Grignard Reactor | SLGS001 | SLGS002 | SLGS50 | SLGS100 |

| Liquid Holdup(L) | 1 | 2 | 50 | 100 | |

| Production Capacity(t/a) | 40 | 100 | 2000 | 4000 | |

| Design Pressure(MPa) | 0-2MPa | ||||

| Design Temperature(℃) | -20~200 | ||||

| Reactor Plate Material | 316L | ||||

| Rotation Speed (rpm) | 0~600r/min | ||||

| Seal Type | Magnetic Seal | ||||

| Structural Dimensions(mm) | 800*600*1800 | 1000*800*2500 | |||

| Applicable Reaction Types | Grignard Reaction | ||||

Previous page

Next page

Precision Flow, Modular Systems,Green Synthesis

Patents

Industrial Cases

Clients

Chemical Reactions Supported

Why Choose PMG ChemTech?

Lead the Future of Continuous Flow Technology

Industry-Leading Full-Scenario Solutions

At PMG ChemTech, we don’t just build reactors—we revolutionize chemical manufacturing. With the most comprehensive portfolio of continuous flow reactors in the industry, we deliver tailored “one-stop” solutions for sectors ranging from pharmaceuticals and agrochemicals to specialty materials and green chemistry.

Core Technologies Driving Industrial Innovation

● Fluid Dynamics Expertise

● Synthesis & Scale-Up Mastery

● Separation Precision

● Engineering Excellence

The PMG Advantage: Brains Behind the Breakthroughs

6 PhDs, 5 senior engineers, and multidisciplinary experts in organic synthesis, chemical engineering, automation, and fluid mechanics.

Trusted by Global Leaders

With 30+ patents, 50+ industrial success stories, and partnerships spanning 150+ clients, PMG ChemTech has optimized 400+ chemical reactions worldwide. From Fortune 500 giants to innovative SMEs, we empower industries to embrace continuous, automated, and intelligent manufacturing.

Join the Continuous Flow Revolution

Why settle for outdated batch processes? PMG ChemTech equips you with the technology to:

✅ Slash operational costs by 30-50%

✅ Reduce carbon footprint through energy-efficient designs

✅ Eliminate safety risks with automated, closed-loop systems

✅ Accelerate time-to-market with rapid scale-up capabilities

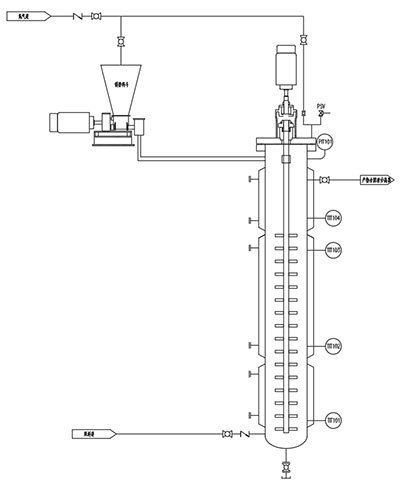

A comprehensive service system

Whether it's technical consultation or business inquiries, we promise to provide an initial response within 24 hours. From laboratory testing to industrial production, we offer one-stop services to ensure seamless integration at every stage.

Ready to Transform Your Chemical Processes?

Contact Us Today for a FREE Consultation or Request a Customized Solution!

GET IN TOUCHPrecision Manufacturing

Interested in our product

Enter your contact information and we will contact you as soon as possible

Science Laboratory

Packaging and transportation

Other Products

PMG ChemTech is committed to driving the global chemical industry towards continuous, automated, and intelligent transformation, offering efficient, safe, and sustainable chemical manufacturing solutions to our clients