PRODUCTS

Contact Us

Phone

Address

No. 60, Yunjing East Road, Liyuan Town, Tongzhou District, Beijing City, China

PGA

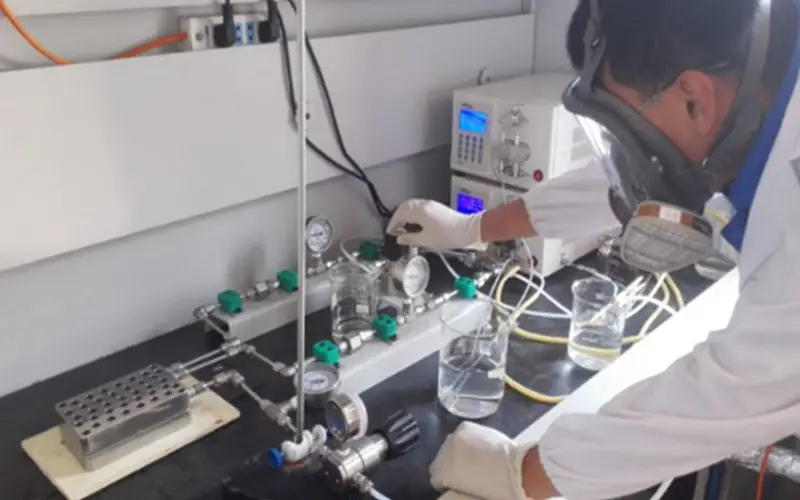

Utilizing continuous flow reactor technology.

keywords:

Category:

Chemical Reagents

Medical-grade Biodegradable Polymers

1. Continuous Flow Technology & Biodegradable Polymers

Utilizing continuous flow reactor technology, we achieve precise control over high-purity monomer synthesis and polymerization processes, ensuring batch consistency ≥99.9% to meet stringent FDA/CE requirements for implantable medical materials. Our high-performance biodegradable polymers are widely used in absorbable sutures, drug delivery systems (DDS), cosmetic microspheres, orthopedic fixation devices, and tissue engineering scaffolds.

2. Core Product Matrix

| Product Series | Key Properties | Applications |

| PGA (Polyglycolic Acid) | High crystallinity (≥80%), tensile strength ≥1.2 GPa, degradation period: 6–12 months | Absorbable surgical sutures, orthopedic bone nails, hernia repair meshes |

| PGLA (Glycolide-Lactide Copolymer) | Adjustable glycolide/lactide ratio (90/10 to 30/70), controlled degradation (3 weeks–6 months) | Absorbable sutures (e.g., Vicryl™-type), drug-loaded microspheres, tissue scaffolds |

| PPDO (Polyp-dioxanone) | Superior flexibility (elongation at break ≥300%), degradation period: 4–6 months | Monofilament sutures (e.g., PDS II™-type), cardiovascular stent coatings, soft tissue repair |

| PCL (Polycaprolactone) | Ultra-long degradation period (2–4 years), low-temperature plasticity (melting point: 60–70°C) | Long-lasting cosmetic fillers, trauma repair membranes, pediatric absorbable implants |

| PLLA (Poly-L-lactic Acid) | High rigidity (elastic modulus ≥3.5 GPa), degradation period: 18–36 months | Orthopedic plates/screws, dental implants, 3D-printed tissue engineering scaffolds |

| PDLA (Poly-D-lactic Acid) | Forms stereocomplexes with PLLA (Tm ↑ to 220°C), enhanced heat resistance | High-temperature sterilization devices, drug carriers requiring heat processing |

| PLCL (L-lactide-Caprolactone Copolymer) | Tunable elastic modulus (0.1–1.5 GPa), degradation period: 6–24 months | Vascular stents, artificial skin, elastic soft tissue repair materials |

| PDCL (p-Dioxanone-Caprolactone Copolymer) | Combines PPDO flexibility with PCL degradation controllability (Tg adjustable: -10°C to 20°C) | Cardiovascular sutures, nerve conduits, absorbable hemostatic clips |

| PGCL (Glycolide-Caprolactone Copolymer) | Excellent hydrophilicity (contact angle ≤50°), degradation period: 1–6 months | Ophthalmic absorbable sutures, wound dressings, vaccine delivery carriers |

3. Four Core Advantages

● Full Industry Chain Integration

Vertical control from monomer synthesis → polymerization → finished product processing, reducing costs by 30% and enabling lead time ≤1 month (industry average: 6+ months). Continuous flow technology ensures zero batch variation, purity ≥99.5%, and monomer residue ≤1%.

● Medical-grade Compliance

ISO 13485 certified, passes full suite of NAMSA biocompatibility tests (cytotoxicity, sensitization, irritation). Production environment meets SGS cleanliness standards (Class 10,000).

● Deep Customization Capabilities

Adjustable parameters: intrinsic viscosity (IV: 0.5–3.5 dl/g), copolymer ratios, particle morphology (powder/spherical granules). Provides end-to-end regulatory support (e.g., FDA 510(k) submissions).

● Global Delivery Network

Direct shipping from Qingdao Free Trade Zone, customs clearance within 72 hours for major global ports, with DDP/DAP terms available.

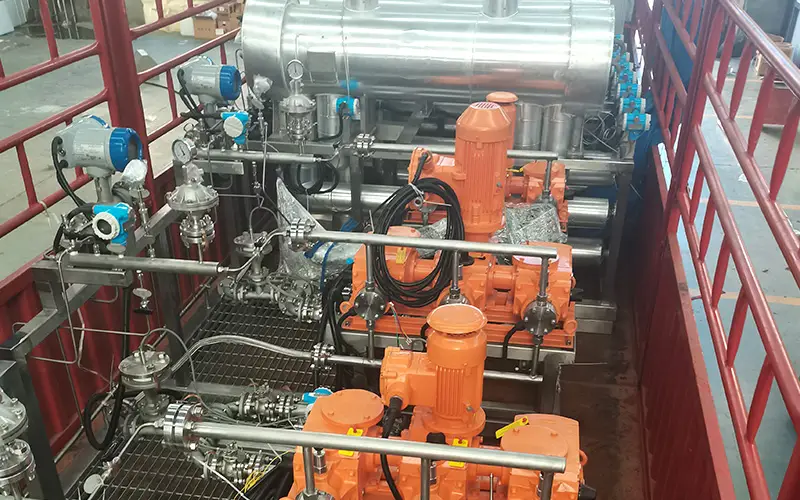

Precision Flow, Modular Systems,Green Synthesis

Patents

Industrial Cases

Clients

Chemical Reactions Supported

Why Choose PMG ChemTech?

Lead the Future of Continuous Flow Technology

Industry-Leading Full-Scenario Solutions

At PMG ChemTech, we don’t just build reactors—we revolutionize chemical manufacturing. With the most comprehensive portfolio of continuous flow reactors in the industry, we deliver tailored “one-stop” solutions for sectors ranging from pharmaceuticals and agrochemicals to specialty materials and green chemistry.

Core Technologies Driving Industrial Innovation

● Fluid Dynamics Expertise

● Synthesis & Scale-Up Mastery

● Separation Precision

● Engineering Excellence

The PMG Advantage: Brains Behind the Breakthroughs

6 PhDs, 5 senior engineers, and multidisciplinary experts in organic synthesis, chemical engineering, automation, and fluid mechanics.

Trusted by Global Leaders

With 30+ patents, 50+ industrial success stories, and partnerships spanning 150+ clients, PMG ChemTech has optimized 400+ chemical reactions worldwide. From Fortune 500 giants to innovative SMEs, we empower industries to embrace continuous, automated, and intelligent manufacturing.

Join the Continuous Flow Revolution

Why settle for outdated batch processes? PMG ChemTech equips you with the technology to:

✅ Slash operational costs by 30-50%

✅ Reduce carbon footprint through energy-efficient designs

✅ Eliminate safety risks with automated, closed-loop systems

✅ Accelerate time-to-market with rapid scale-up capabilities

A comprehensive service system

Whether it's technical consultation or business inquiries, we promise to provide an initial response within 24 hours. From laboratory testing to industrial production, we offer one-stop services to ensure seamless integration at every stage.

Ready to Transform Your Chemical Processes?

Contact Us Today for a FREE Consultation or Request a Customized Solution!

GET IN TOUCHPrecision Manufacturing

Interested in our product

Enter your contact information and we will contact you as soon as possible

Science Laboratory

Packaging and transportation

Other Products

PMG ChemTech is committed to driving the global chemical industry towards continuous, automated, and intelligent transformation, offering efficient, safe, and sustainable chemical manufacturing solutions to our clients